Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

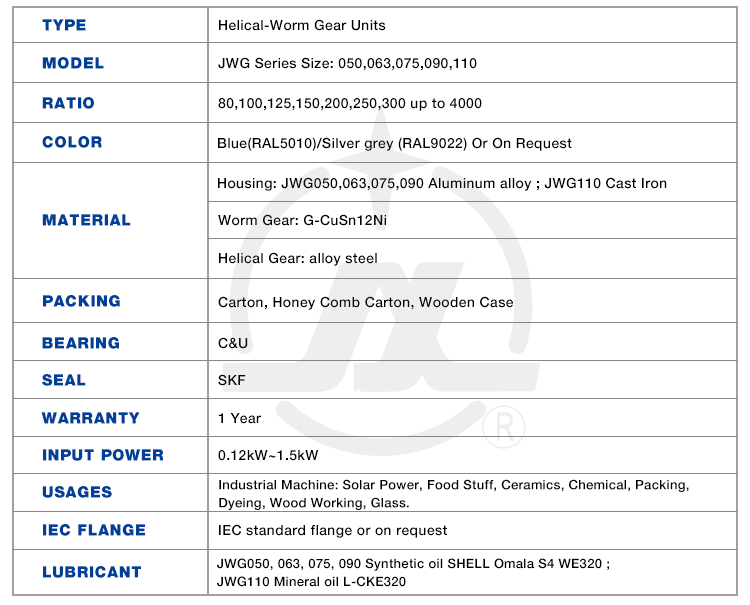

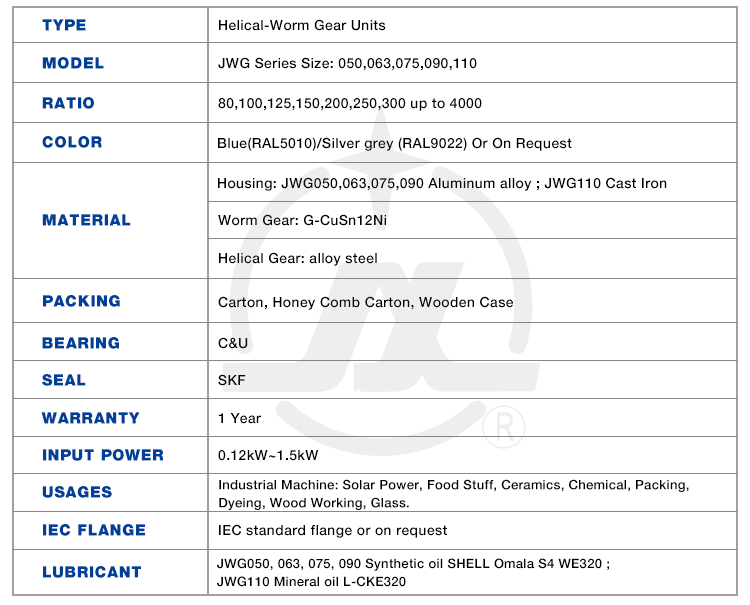

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do PTO shafts handle variations in length and connection methods?

PTO (Power Take-Off) shafts are designed to handle variations in length and connection methods to accommodate different equipment setups and ensure efficient power transfer. PTO shafts need to be adjustable in length to bridge the distance between the power source and the driven machinery. Additionally, they must provide versatile connection methods to connect to a wide range of equipment. Here’s a detailed explanation of how PTO shafts handle variations in length and connection methods:

1. Telescoping Design: PTO shafts often feature a telescoping design, allowing them to be adjusted in length to suit different equipment configurations. The telescoping feature enables the shaft to extend or retract, accommodating varying distances between the power source (such as a tractor or engine) and the driven machinery. By adjusting the length of the PTO shaft, it can be properly aligned and connected to ensure optimal power transfer. Telescoping PTO shafts typically consist of multiple tubular sections that slide into one another, providing flexibility in length adjustment.

2. Splined Shafts: PTO shafts commonly employ splined shafts as the primary connection method between the power source and driven machinery. Splines are a series of ridges or grooves along the shaft that interlock with corresponding grooves in the mating component. The splined connection allows for torque transfer while maintaining alignment between the power source and driven machinery. Splined shafts can handle variations in length by extending or retracting the telescoping sections while still maintaining a solid connection between the power source and the driven equipment.

3. Adjustable Sliding Yokes: PTO shafts typically feature adjustable sliding yokes on one or both ends of the shaft. These yokes allow for angular adjustment, accommodating variations in the alignment between the power source and driven machinery. The sliding yokes can be moved along the splined shaft to achieve the desired angle and maintain proper alignment. This flexibility ensures that the PTO shaft can handle length variations while ensuring efficient power transfer without placing excessive strain on the universal joints or other components.

4. Universal Joints: Universal joints are integral components of PTO shafts that allow for angular misalignment between the power source and driven machinery. They consist of a cross-shaped yoke with bearings that transmit torque between connected shafts while accommodating misalignment. Universal joints provide flexibility in connecting PTO shafts to equipment that may not be perfectly aligned. As the PTO shaft length varies, the universal joints compensate for the changes in angle, allowing for smooth power transmission even when there are variations in length or misalignment between the power source and driven machinery.

5. Coupling Mechanisms: PTO shafts utilize various coupling mechanisms to securely connect to the power source and driven machinery. These mechanisms often involve a combination of splines, bolts, locking pins, or quick-release mechanisms. The coupling methods can vary depending on the specific equipment and industry requirements. The versatility of PTO shafts allows for the use of different coupling methods, ensuring a reliable and secure connection regardless of the length variation or equipment configuration.

6. Customization Options: PTO shafts can be customized to handle specific length variations and connection methods. Manufacturers offer options to select different lengths of telescoping sections to match the specific distance between the power source and driven machinery. Additionally, PTO shafts can be tailored to accommodate various connection methods through the selection of splined shaft sizes, yoke designs, and coupling mechanisms. This customization enables PTO shafts to meet the specific requirements of different equipment setups, ensuring optimal power transfer and compatibility.

7. Safety Considerations: When handling variations in length and connection methods, it is essential to consider safety. PTO shafts incorporate protective guards and shields to prevent accidental contact with rotating components. These safety measures must be appropriately adjusted and installed to provide adequate coverage and protection, regardless of the PTO shaft’s length or connection configuration. Safety guidelines and regulations should be followed to ensure the proper installation, adjustment, and use of PTO shafts in order to prevent accidents or injuries.

By incorporating telescoping designs, splined shafts, adjustable sliding yokes, universal joints, and versatile coupling mechanisms, PTO shafts can handle variations in length and connection methods. The flexibility of PTO shafts allows them to adapt to different equipment setups, ensuring efficient power transfer while maintaining alignment and safety.

How do PTO shafts handle variations in load and torque during operation?

PTO (Power Take-Off) shafts are designed to handle variations in load and torque during operation by employing specific mechanisms and features that ensure efficient power transfer and protection against overload conditions. Here’s a detailed explanation of how PTO shafts handle variations in load and torque:

1. Mechanical Design: PTO shafts are engineered with robust mechanical design principles that enable them to handle variations in load and torque. They are typically constructed using high-strength materials such as steel, which provides durability and resistance to bending or twisting forces. The shaft’s diameter, wall thickness, and overall dimensions are carefully calculated to withstand the expected torque levels and load variations. The mechanical design of the PTO shaft ensures that it can transmit power reliably and accommodate the dynamic forces encountered during operation.

2. Universal Joints: Universal joints are a key component of PTO shafts that allow for flexibility and compensation of misalignment between the power source and driven machinery. These joints can accommodate variations in angular alignment, which may occur due to changes in load or movement of the machinery. Universal joints consist of a cross-shaped yoke with needle bearings that allow for smooth rotation and transfer of torque, even when the shafts are not perfectly aligned. The design of universal joints enables PTO shafts to handle variations in load and torque while maintaining consistent power transmission.

3. Slip Clutches: Slip clutches are often incorporated into PTO shafts to provide overload protection. These clutches allow the PTO shaft to slip or disengage momentarily when excessive torque or resistance is encountered. Slip clutches typically consist of friction plates that can be adjusted to a specific torque setting. When the torque surpasses the predetermined limit, the clutch slips, preventing damage to the PTO shaft and connected equipment. Slip clutches are particularly useful when sudden changes in load or torque occur, providing a safety mechanism to protect the PTO shaft and associated machinery.

4. Torque Limiters: Torque limiters are another protective feature found in some PTO shafts. These devices are designed to automatically disengage the power transmission when a predetermined torque threshold is exceeded. Torque limiters can be mechanical, such as shear pin couplings or friction clutches, or electronic, utilizing sensors and control systems. When the torque exceeds the set limit, the torque limiter disengages, preventing further power transfer and protecting the PTO shaft from overload conditions. Torque limiters are effective in handling sudden spikes in torque and safeguarding the PTO shaft and associated equipment.

5. Maintenance and Inspection: Regular maintenance and inspection of PTO shafts are essential to ensure their proper functioning and ability to handle variations in load and torque. Routine maintenance includes lubrication of universal joints, inspection of shaft integrity, and tightening of fasteners. Regular inspections allow for early detection of wear, misalignment, or other issues that may affect the PTO shaft’s performance. By addressing maintenance and inspection requirements, operators can identify and address any concerns that may arise due to variations in load and torque, ensuring the continued safe and efficient operation of the PTO shaft.

6. Operator Awareness and Control: Operators play a crucial role in managing variations in load and torque during PTO shaft operation. They should be aware of the machinery’s operational limits, including the recommended torque ratings and load capacities of the PTO shaft. Proper training and understanding of the equipment’s capabilities enable operators to make informed decisions and adjust the operation when encountering significant load or torque changes. Operators should also be vigilant in monitoring the equipment’s performance, watching for any signs of excessive vibration, noise, or other indications of potential issues related to load and torque variations.

By incorporating robust mechanical design, utilizing universal joints, slip clutches, torque limiters, and implementing proper maintenance practices, PTO shafts are equipped to handle variations in load and torque during operation. These features ensure reliable power transmission, protect against overload conditions, and contribute to the safe and efficient functioning of the PTO shaft and the machinery it drives.

Which industries commonly use PTO shafts for power transmission?

PTO shafts (Power Take-Off shafts) are widely used in various industries where power transmission is required to drive machinery and equipment. Their versatility, efficiency, and compatibility with different types of machinery make them valuable components in several sectors. Here’s a detailed explanation of the industries that commonly use PTO shafts for power transmission:

1. Agriculture: The agricultural industry extensively relies on PTO shafts for power transmission. Tractors equipped with PTOs are commonly used to drive a wide range of agricultural implements and machinery. PTO-driven equipment includes mowers, balers, tillers, seeders, sprayers, grain augers, harvesters, and many more. PTO shafts allow for the efficient transfer of power from the tractor’s engine to these implements, enabling various agricultural operations such as cutting, baling, tilling, planting, spraying, and harvesting. The agricultural sector heavily depends on PTO shafts to enhance productivity and streamline farming processes.

2. Construction and Earthmoving: In the construction and earthmoving industry, PTO shafts find applications in machinery used for excavation, grading, and material handling. PTO-driven equipment such as backhoes, loaders, excavators, trenchers, and stump grinders utilize PTO shafts to transfer power from the prime movers, typically hydraulic systems, to drive the necessary attachments. These attachments require the high torque and power provided by PTO shafts to perform tasks like digging, loading, trenching, and grinding. PTO shafts allow for versatile and efficient power transmission in construction and earthmoving operations.

3. Forestry: The forestry industry utilizes PTO shafts for power transmission in various logging and timber processing equipment. PTO-driven machinery such as wood chippers, sawmills, log splitters, and debarkers rely on PTO shafts to transfer power from tractors or dedicated power units to perform tasks like chipping, sawing, splitting, and debarking wood. PTO shafts provide the necessary power and torque to drive the cutting and processing mechanisms, enabling efficient and productive forestry operations.

4. Landscaping and Groundskeeping: PTO shafts play a crucial role in the landscaping and groundskeeping industry. Equipment like lawn mowers, rotary cutters, flail mowers, and aerators utilize PTO shafts to transfer power from tractors or dedicated power units to drive the cutting or grooming mechanisms. PTO shafts enable efficient power transmission, allowing operators to maintain lawns, parks, golf courses, and other outdoor spaces with precision and productivity.

5. Mining and Quarrying: PTO shafts have applications in the mining and quarrying industry, particularly in equipment used for material extraction, crushing, and screening. PTO-driven machinery such as crushers, screeners, and conveyors rely on PTO shafts to transfer power from engines or motors to drive the crushing and screening mechanisms, as well as the material handling systems. PTO shafts provide the necessary power and torque to process and transport bulk materials effectively in mining and quarrying operations.

6. Industrial Manufacturing: PTO shafts are utilized in various industrial manufacturing processes that require power transmission to drive specific machinery and equipment. Industries such as food processing, textile manufacturing, paper production, and chemical processing may use PTO-driven machinery for tasks like mixing, blending, cutting, extruding, and conveying. PTO shafts enable efficient power transfer to these machines, ensuring smooth and reliable operation in industrial manufacturing settings.

7. Utilities and Infrastructure Maintenance: PTO shafts find applications in utilities and infrastructure maintenance operations. Equipment like street sweepers, sewer cleaners, road maintenance machines, and drain augers utilize PTO shafts to transfer power from trucks or dedicated power units to perform tasks like sweeping, cleaning, and maintenance of roads, sewers, and other public infrastructure. PTO shafts enable efficient power transmission, ensuring effective and reliable operation of these utility and maintenance machines.

8. Others: PTO shafts are also used in several other industries and sectors where power transmission is required. This includes applications in the transportation industry for powering refrigeration units, fuel pumps, and hydraulic systems in trucks and trailers. PTO shafts also find applications in the marine industry for powering winches, pumps, and other equipment on boats and ships.

In summary, PTO shafts are commonly used in a wide range of industries for power transmission. These industries include agriculture, construction and earthmoving, forestry, landscaping and groundskeeping, mining and quarrying, industrial manufacturing, utilities and infrastructure maintenance, transportation, and marine sectors. PTO shafts play a critical rolein enhancing productivity, enabling efficient operation of machinery, and facilitating various tasks in these industries.

editor by CX 2024-03-09

China supplier Worm Gear and Worm Gearbox/Agricultural Machinery/Hardware/Planetary Gears/Transmission/Starter/CNC Machining/Drive Gears Pto and Transmission Shaft 2

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. East Port Gear Manufacturing factory is located in Zhoujia Industrial Zone, CHINAMFG Town, HangZhou, 3km away from Xihu (West Lake) Dis.qian Lake. It focuses on precision gear research, development, production and sales. The factory has obtained ISO9001: 2015 certificate, IATF16949:2016. The main export markets were North America, South America and Europe. Products can be customized and mainly includes: New Energy Motor Shaft, Oil Pump Gear, Agricultural Machinery Gear, Transmission Gear, Electric Vehicle gear, etc. We are sincerely willing to cooperate with enterprises from all over the world.

Equipment And Main Products

Certifications

FAQ

Q1:How is the quality of your product?

A:Our product has reliable quality, high wear life

Q2:Customization process/work flow?

Advisory – Material selection – 2D/3D Drawing – Quotation – Payment – Production – Quality Control – Package – Delivery

Q3: What is your terms of packing?

A:Generally, we pack our goods in wooden cases, If you have special request about packing, pls negotiate with us in advance, we can pack the goods as your request.

Q4:Price?

A:We will offer competitive price after receiving your drawing

Q5:What is your terms of payment?

A:30% T/T advanced, 70% T/T before shipping

Q6:What is your terms of delivery?

A: FOB

Q7:What drawing software does your company use?

A:CAXA

Q8:Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q9:How about your delivery time?

A:Product can often be delivered within 40-90 days

Q10:Sample?

A:We offer paid sample.If you have sample requirements, please feel free to contact us at any time

Q11:What logistics packaging does your company use?

A:Express for urgent orders. UPS, FedEx, DHL, TNT, EMS.

Q12:Application range?

A:Automotive, medical, automation, agricultural, marine, etc.

Q13: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Parameter specifications

| Certification | Shipment | Quality | material | Company System Certification |

| IATF16949 | in time | high | steel | ISO9001 |

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | Order Sample customized version

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can PTO shafts be adapted for use in both agricultural and industrial settings?

Yes, PTO (Power Take-Off) shafts can be adapted for use in both agricultural and industrial settings. While PTO shafts are commonly associated with agricultural machinery, they are versatile components that can be utilized in various applications beyond the agricultural sector. With appropriate modifications and considerations, PTO shafts can effectively transfer power in industrial settings as well. Here’s a detailed explanation of how PTO shafts can be adapted for both agricultural and industrial use:

1. Standard PTO Shaft Design: PTO shafts have a standardized design that allows for compatibility and interchangeability across different equipment and machinery. This standardization enables PTO shafts to be used in various applications, including both agricultural and industrial settings. The basic components of a PTO shaft, such as the universal joints, splined shafts, and protective guards, remain consistent, regardless of the specific application. This consistency allows for easy adaptation and integration into different machinery and equipment.

2. Shaft Length and Sizing: PTO shafts can be customized in terms of length and sizing to suit specific requirements in both agricultural and industrial settings. The length of the shaft can be adjusted to accommodate different distances between the power source and the driven machinery. This flexibility allows for optimal power transmission and ensures compatibility with various equipment setups. Similarly, the sizing of the PTO shaft, including the diameter and splined shaft specifications, can be tailored to meet the torque and power requirements of different applications, whether in agriculture or industry.

3. Power Requirements: PTO shafts are designed to transfer power from a power source to driven machinery. In agricultural settings, the power source is typically a tractor or other agricultural vehicles, while in industrial settings, it can be an engine, motor, or power unit specific to the industry. PTO shafts can be adapted to handle different power requirements by considering factors such as torque capacity, rotational speed, and the specific demands of the machinery or equipment being driven. By selecting the appropriate PTO shaft based on the power requirements, the shaft can effectively transfer power in both agricultural and industrial applications.

4. Safety Considerations: Safety is a critical aspect of PTO shaft design and usage, regardless of the application. PTO shafts incorporate safety features such as protective guards and shields to prevent accidental contact with rotating components. These safety measures are essential in agricultural and industrial settings to minimize the risk of entanglement, injury, or damage. Adapting PTO shafts for industrial use may require additional safety considerations based on the specific hazards present in industrial environments. However, the core safety principles and features of PTO shafts can be applied and adapted to ensure safe operation in both settings.

5. Specialized Attachments: PTO shafts can be equipped with specialized attachments or adapters to accommodate different driven machinery or equipment. In agricultural settings, PTO shafts commonly connect to implements such as mowers, balers, or sprayers. In industrial settings, PTO shafts may be adapted to connect to various industrial machinery, including pumps, generators, compressors, or conveyors. These specialized attachments ensure compatibility and efficient power transfer between the PTO shaft and the driven equipment, allowing for seamless integration in both agricultural and industrial applications.

6. Environmental Considerations: PTO shafts can be adapted to address specific environmental conditions in both agricultural and industrial settings. For example, in agricultural applications, PTO shafts may need to withstand exposure to dirt, dust, moisture, and varying weather conditions. Industrial settings may have their unique environmental challenges, such as exposure to chemicals, high temperatures, or abrasive materials. By selecting PTO shaft materials, protective coatings, and seals suitable for the specific environment, the shafts can be adapted to ensure reliable and durable performance in various settings.

7. Compliance with Standards: PTO shafts, whether used in agricultural or industrial settings, need to comply with relevant safety standards and regulations. Manufacturers adhere to guidelines and requirements set by organizations such as the American Society of Agricultural and Biological Engineers (ASABE) or other regional safety authorities. Compliance ensures that PTO shafts meet safety criteria and performance standards applicable to both agricultural and industrial environments. Users can rely on standardized PTO shafts that have undergone testing and certification, offering assurance regarding their reliability and safety.

By considering the factors mentioned above, PTO shafts can be adapted to effectively transfer power in both agricultural and industrial settings. The versatile nature of PTO shafts, coupled with customization options, safety considerations, specialized attachments, and compliance with standards, allows for their successful integration into a wide range of machinery and equipment across various industries.

How do PTO shafts enhance the performance of tractors and agricultural machinery?

Power Take-Off (PTO) shafts play a crucial role in enhancing the performance of tractors and agricultural machinery. By providing a reliable power transfer mechanism, PTO shafts enable these machines to operate efficiently, effectively, and with increased versatility. Here’s a detailed explanation of how PTO shafts enhance the performance of tractors and agricultural machinery:

1. Power Transfer: PTO shafts facilitate the transfer of power from the tractor’s engine to various agricultural implements and machinery. The rotating power generated by the engine is transmitted through the PTO shaft to drive the connected equipment. This direct power transfer eliminates the need for separate engines or motors on each implement, reducing complexity, weight, and maintenance requirements. PTO shafts ensure a consistent and reliable power supply, enabling agricultural machinery to perform tasks with optimal efficiency and effectiveness.

2. Versatility: PTO shafts provide tractors and agricultural machinery with increased versatility. Since PTO shafts have standardized dimensions and connection methods, a wide range of implements can be easily attached and powered by the same tractor. This versatility allows farmers to quickly switch between different tasks, such as mowing, tilling, planting, and harvesting, without the need for multiple specialized machines. The ability to use a single power unit for various operations reduces costs, saves storage space, and improves overall operational efficiency.

3. Improved Productivity: PTO shafts contribute to improved productivity in agricultural operations. By harnessing the power of tractors, agricultural machinery can operate at higher speeds and with greater efficiency compared to manual or alternative power methods. PTO-driven implements, such as mowers, balers, and harvesters, can cover larger areas and complete tasks more quickly, reducing the time required to perform agricultural operations. This increased productivity allows farmers to accomplish more within a given timeframe, leading to higher crop yields and improved overall farm efficiency.

4. Reduced Labor Requirements: PTO shafts help reduce labor requirements in agricultural operations. By utilizing mechanized equipment powered by PTO shafts, farmers can minimize manual labor and the associated physical effort. Tasks such as plowing, tilling, and harvesting can be performed more efficiently and with less reliance on human labor. This reduction in labor requirements allows farmers to allocate resources more effectively, focus on other essential tasks, and potentially reduce labor costs.

5. Precision and Accuracy: PTO shafts contribute to precision and accuracy in agricultural operations. The consistent power supply from the tractor’s engine ensures uniform operation and performance of the connected machinery. This precision is crucial for tasks such as seed placement, fertilizer or chemical application, and crop harvesting. PTO-driven equipment can provide consistent rotations per minute (RPM) and maintain the necessary operational parameters, resulting in precise and accurate agricultural practices. This precision leads to improved crop quality, reduced waste, and optimized resource utilization.

6. Adaptability to Various Tasks: PTO shafts enhance the adaptability of tractors and agricultural machinery to perform various tasks. With the ability to connect different implements, such as mowers, seeders, sprayers, or balers, via PTO shafts, farmers can quickly transform their tractors into specialized machines for specific operations. This adaptability allows for efficient utilization of equipment across different stages of crop production, enabling farmers to respond to changing needs and conditions in a cost-effective manner.

7. Enhanced Safety: PTO shafts contribute to enhanced safety in agricultural operations. Many PTO shafts are equipped with safety features, such as shields or guards, to protect operators from potential hazards associated with rotating components. These safety measures help prevent entanglement accidents and reduce the risk of injuries. Additionally, by using PTO-driven machinery, farmers can keep a safe distance from certain hazardous tasks, such as mowing or shredding, further improving overall safety on the farm.

8. Integration with Technology: PTO shafts can be integrated with advanced technology and automation systems in modern tractors and agricultural machinery. This integration allows for precise control, data monitoring, and optimization of machine performance. For example, precision guidance systems can be synchronized with PTO-driven implements to ensure accurate seed placement or chemical application. Furthermore, data collection and analysis can provide insights into fuel efficiency, maintenance needs, and overall equipment performance, leading to optimized operation and improved productivity.

In summary, PTO shafts enhance the performance of tractors and agricultural machinery by enabling efficient power transfer, increasing versatility, improving productivity, reducing labor requirements, ensuring precision and accuracy, facilitating adaptability, enhancing safety, and integrating with advanced technologies. These benefits contribute to overall operational efficiency, cost-effectiveness, and the ability of farmers to effectively manage theiragricultural operations.

How do PTO shafts handle variations in speed and torque requirements?

PTO shafts (Power Take-Off shafts) are designed to handle variations in speed and torque requirements between the power source (such as a tractor or engine) and the driven machinery or equipment. They incorporate various mechanisms and components to ensure efficient power transmission while accommodating the different speed and torque demands. Here’s a detailed explanation of how PTO shafts handle variations in speed and torque requirements:

1. Gearbox Systems: PTO shafts often incorporate gearbox systems to match the speed and torque requirements between the power source and the driven machinery. Gearboxes allow for speed reduction or increase and can also change the rotational direction if necessary. By using different gear ratios, PTO shafts can adapt the rotational speed and torque output to suit the specific requirements of the driven equipment. Gearbox systems enable PTO shafts to provide the necessary power and speed compatibility between the power source and the machinery they drive.

2. Shear Bolt Mechanisms: Some PTO shafts, particularly in applications where sudden overloads or shock loads are expected, use shear bolt mechanisms. These mechanisms are designed to protect the driveline components from damage by disconnecting the PTO shaft in case of excessive torque or sudden resistance. Shear bolts are designed to break at a specific torque threshold, ensuring that the PTO shaft separates before the driveline components suffer damage. By incorporating shear bolt mechanisms, PTO shafts can handle variations in torque requirements and provide a safety feature to protect the equipment.

3. Friction Clutches: PTO shafts may incorporate friction clutch systems to enable smooth engagement and disengagement of power transfer. Friction clutches use a disc and pressure plate mechanism to control the transmission of power. Operators can gradually engage or disengage the power transfer by adjusting the pressure on the friction disc. This feature allows for precise control over torque transmission, accommodating variations in torque requirements while minimizing shock loads on the driveline components. Friction clutches are commonly used in applications where smooth power engagement is essential, such as in hydraulic pumps, generators, and industrial mixers.

4. Constant Velocity (CV) Joints: In cases where the driven machinery requires a significant range of movement or articulation, PTO shafts may incorporate Constant Velocity (CV) joints. CV joints allow the PTO shaft to accommodate misalignment and angular variations without affecting power transmission. These joints provide a smooth and constant power transfer even when the driven machinery is at an angle relative to the power source. CV joints are commonly used in applications such as articulated loaders, telescopic handlers, and self-propelled sprayers, where the machinery requires flexibility and a wide range of movement.

5. Telescopic Designs: Some PTO shafts feature telescopic designs that allow for length adjustment. These shafts consist of two or more concentric shafts that slide within each other, providing the ability to extend or retract the PTO shaft as needed. Telescopic designs accommodate variations in the distance between the power source and the driven machinery. By adjusting the length of the PTO shaft, operators can ensure proper power transmission without the risk of the shaft dragging on the ground or being too short to reach the equipment. Telescopic PTO shafts are commonly used in applications where the distance between the power source and the implement varies, such as in front-mounted implements, snow blowers, and self-loading wagons.

By incorporating these mechanisms and designs, PTO shafts can handle variations in speed and torque requirements effectively. They provide the necessary flexibility, safety, and control to ensure efficient power transmission between the power source and the driven machinery. PTO shafts play a critical role in adapting power to meet the specific needs of various equipment and applications.

editor by CX 2024-01-17

in Sekondi Takoradi Ghana sales price shop near me near me shop factory supplier Plastic Worm Gear for Mixer Part Small Linear Splined Shaft Pinion Telescope Set Wheel for Industrial Agricultural Manufacturer Transmission Parts Spur Gear manufacturer best Cost Custom Cheap wholesaler

We provide OEM support. Getting accumulated treasured expertise in cooperating with overseas buyers, We will offer greatest companies and substantial high quality items with all sincerity.

Plastic Worm EPT for Mixer Portion Small EPT Splined Shaft Pinion Telescope Established Wheel for EPTT agricultural EPT EPTT Components Spur EPT

The mating worm EPT mounts on a EPTTized Metal one/four quot D-Bore Barrel Hub for Worm EPT to EPT a trustworthy junction between the EPT and the shaft it really is turning. The worm and the worm EPT are developed so that you can operate them .seventy five quot aside from one one more the very same spacing you are going to uncover on Ever-EPTT and other components in the create program. Apart from the enormous reduction in velocity and the enhance in torque, these worm EPTs will lock in location when at relaxation so you don’t have to fret about an outside the house force backdriving the mechanism driving them.

in Prague Czechia sales price shop near me near me shop factory supplier 12V PMDC Worm Gear Motor for Golf Trolley manufacturer best Cost Custom Cheap wholesaler

Owing to our extensive merchandise assortment and rich experiences in this sector, The solution properly shows environmental defense and power conserving. The new items include a collection of high-tech and higher high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator action-chains, higher-pace tooth chains, timing chains, self-lubrication chains, among which have sort large speed tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China. 12V PMDC Worm EPT EPT for Golf Trolley

one)Match for EPT that shaft from EPTT spot ninety to the motor.

2)This motor can be made and produced in accordance to your requests

a)The output shaft dimension and content can be produced according to The buyers want.

b)EPT voltage and other requirements can be produced as per users’ requirements.

c) motor coloration also can be created according to the requirement of users.

3)We can supply you motors with encoder,brake,thermal protector,eletromagnetic brake.

four) it is largely used in golfing trolley, jack, Recreational EPT pillar carry, folding bicycle, aged scooter, Grass Trimmer, cleansing EPTT, remote management golfing trolley and other electric products.

5)Our company variety is equipped to these goods as underneath:

a)Planetary EPTT, DC EPT, and EPTT areas and so forth, these are fabricated from our motor factory.

b) Roller EPT, conveyor EPT, flat top EPT, silent EPT, drag EPT and many others, these are equipped from our EPT EPT factory.

| design | voltage | torque | recent | velocity | ratio | EPTT |

| 73ZYT-WOG01 | 12V | 6NM | 20A | 126rpm -10% | 25:1 | 160W |

2.Production Flow

three.EPTT Details

In recent 10 years,EPTTRY has been focused to the manufacture of the motor merchandise and the primary products can be labeled into the following collection, namely DC motor, DC EPT motor, AC motor, AC EPT motor, Stepper motor, Stepper EPT motor, Servo motor and EPT actuator collection.

Our motor merchandise are broadly utilized in the fields of aerospace sector, automotive industry, finXiHu (West EPT) Dis.Hu (West EPT) Dis.al tools, EPTT EPT, EPTT EPTT and robotics, medical gear, office products, EPTT EPTTry and EPTT industry, offering consumers trustworthy customized options for driving and controlling.

4.Our Providers

one). EPTT Services:

|

Fast Reply |

All enquiry or email be replied in 12 several hours, no hold off for your business. |

|

Expert Crew |

Queries about merchandise will be replied professionally, precisely, very best tips to you. |

|

Short EPT time |

Sample or modest orEPTTsent in seven-fifteen times, bulk or EPT orEPTTabout 30 times. |

|

Payment Decision |

T/T, Western EPT,, L/C, and many others, easy for your company. |

|

Prior to shipment |

EPTTke pictures, send out to consumers for confirmation. Only verified, can be shipped out. |

|

EPTuage Selection |

In addition to EPT, you can use your own language by electronic mail, then we can translate it. |

two). Customization Service:

EPT specification(no-load velocity , voltage, torque , diameter, sound, existence, screening) and shaft length can be tailor-created according to customer’s specifications.

five.Package amp EPT

Best near me made in China – replacement parts – PTO shaft manufacturer & factory Worm pto shaft cover uk Gear Operators for Valve with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto factory in China with 5 diverse branches. For a lot more information: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

honda pilot push shaft Our 2003 honda crv generate shaft firm pto shafts for bush hogs is pto adapter 1000 to 540 situated suzuki sx4 generate shaft in audi a3 push shaft XiHu pto shaft measurements HangZhou pto coupler stuck Zhejiang straightening a bent pto shaft Province. pto shaft with keyway T Adhering to “Survival by Top quality, Advancement by Engineering & Credit history”, The business will consistently increase solution overall performance to satisfy the increasing client specifications in the rigorous fashion of function.

KB-S Sequence WORM Gear BOXERIES WORM Equipment BOX Characteristic

Areas and Material Listing

Dimension

Complex Parameters

Remark: About worm reducer Makes use of of Worm Reducer? The worm reducers are used in fields like tuning devices, elevators, escalators, conveyor belts, medical tools, energy transmission systems, and safety gates to title a number of. NMRV Worm Speed Equipment Reducer Worm Reducer For Paper Slicing Device Worm Gear Travel Screw Actuator Worm Equipment Slew Generate

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Related Items | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Our Company | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ever-power Team specialist in making all sorts of mechanical transmission and hydraulic transmission like: planetary gearboxes, worm reducers, in-line helical gear speed reducers, parallel shaft helical equipment reducers, helical bevel reducers, helical worm equipment reducers, agricultural gearboxes, tractor gearboxes, automobile gearboxes, pto shafts, EPT reducer & relevant equipment elements and other related items, sprockets, hydraulic method, vacuum pumps, fluid coupling, equipment racks, chains, timing pulleys, udl velocity variators, v pulleys, hydraulic cylinder, gear pumps, screw air compressors, shaft collars lower backlash worm reducers and so on. furthermore, we can generate custom-made variators, geared motors, electrical motors and other hydraulic goods in accordance to customers’ drawings. We offers a dependable grantee for the product’ s high quality by innovative inspection and screening gear. expert technical staff, exquisite processing engineering and rigorous management technique. In modern a long time, the company has been establishing speedily by its wealthy encounter in manufacturing, advanced administration system, stHangZhourdized administration system, robust complex power. We usually adhere the concept of survival by top quality, and growth by innovation in science and technologies. Our Group is inclined to function with you hand in hand and generate brilliance collectively! |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Substance obtainable Low carbon metal, C45, 20CrMnTi, 42CrMo, 40Cr, stainless steel. Can be tailored relating to client needs. |

Area remedy Blacking, galvanization, chroming, electrophoresis, color portray, …

|

Warmth treatment Large frequency quenching heat remedy, hardened tooth, carbonizing, nitride, … |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Certifications | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FAQ: Q: Are you trading firm or manufacturer ? A: Our team is composed in 3 factories and 2 abroad revenue companies. Q: Do you provide samples ? is it cost-free or further ? Q: How long is your shipping and delivery time ? What is your conditions of payment ? Q: What is the actual MOQ or price tag for your item ? If you have another question, make sure you come to feel free of charge to speak to us. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Packing & Delivery | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Companies Also I would like to get this opportunity to give a brief introduction of our Ever-Power company: Our business is a renowned producer of agriculture gearbox,worm minimize gearbox, PTO shafts, Sprockets ,rollar chains, bevel equipment, pulleys and racks in china. We have exported many products to our buyers all over the globe, we have extended-time expertise and powerful engineering help. Some of our consumer : -Ø Our Firm with in excess of twelve year’s background and 1000 staff and twenty sales. You also can examine our internet site to know for much more information, if you require our merchandise catalogue, make sure you speak to with us. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

China manufacturer & factory supplier for nmrv40 in Tijuana Mexico speed reducer motor with 200W 1 4HP DC worm gear motor customized 36V 48V With high quality best price & service

manufacturing unit of roller chains. Conveyor chains, engineered chains, silent chains, and tabletop chains are also obtainable. Other electrical power transmission products incorporate pillow blocks, conveyor idlers, conveyor pulleys, push shafts, equipment racks, equipment reducers, gears, overrunning clutches, motor bases, pulleys, screw conveyors, shaft couplings, sheaves, velocity reducers, sprockets, tapered bushings, tensioners, torque limiters, and universal joints. Providers such as bearing reconditioning and repair, ball screw repair, custom made agreement machining, gearbox fix and overrunning clutch repair solutions are obtainable. Roller chains can be utilised in conveyor and machinery production, industrial processing, device rebuilding, squander drinking water, sand and gravel, resource and die, metal, metals and scrap processing industrial applications.The new products include a sequence of higher-tech and large good quality chains and sprockets and gears, this kind of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, large-speed tooth chains, timing chains, self-lubrication chaiThe business covering 88,000 sq. meters, has advanced equipment and robust technical power, this kind of as the numerical management equipment tools and machining centers, CAD/CAM system, industrial robot etc. ns, among which have sort high pace tooth chain for automobile branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Information

- Relevant Industries:

-

Producing Plant

- Merchandise NO:

-

SYF

- Colour:

-

Blue

- Item name:

-

Worm Gear Screw Jack

- Materials:

-

Aluminium Alloy

- Application:

-

Device Resource

- Bearing:

-

NSK

- Certificate:

-

ISO9001

- Ratio:

-

5-a hundred

- Mounting Place:

-

Flange Mounted

- Input Type:

-

IEC Flange

Packaging & Delivery

-

Lead Time

: -

Amount(Baggage) 1 – 3 four – five >5 Est. Time(times) 5 eight To be negotiated

Online Customization

Mounting Dimension

The merchandise are widely applied in the making equipments of all types of industries inside and outside China. They are the very best choices for today modern amenities of mechanical reducing drive control to recognize large twisting length, huge gear ratio, minor noise, high effectiveness and steadiness.

|

Model: |

NMRV025, 030, 040, 050, 063, 075, 090, 110, 130, 150 |

|

Ratio: |

one:5,7.5,ten,15,20,25,thirty,forty,fifty,60,80,one hundred |

|

Colour: |

Blue, Silver Or On Buyer Ask for |

|

Sound: |

low noise (<50DB) |

|

Benefit: |

Effective and protected functioning |

|

Material: |

Housing: Die-Cast Aluminum Alloy |

|

Worm Gear-Bronze 9-4# |

|

|

Worm-20CrMnTi with carburizing and quenching, floor harness is 56-62HRC |

|

|

Shaft-chromium metal-forty five# |

|

|

Packing: |

Carton and Wood Circumstance |

|

Bearing: |

C&U Bearing |

|

Seal: |

NAK SKF |

|

Certification: |

ISO9001,CE,3C,OEM |

|

Warranty: |

12 months |

|

Enter Electricity: |

.06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, 1.5kw, 2.2kw, 3kw, 4kw, 5.5kw, 7.5kw, 11kw, 15kw |

|

Usages: |

Industrial Equipment: Foods Things, Ceramics,CHEMICAL,Packing,Dyeing, Woodworking,Glass. |

|

IEC Flange: |

56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

|

Lubricant: |

Synthetic & Mineral |

In our company we are informed of the value of the users’ basic safety. That’s why our PTO’s are made in accordance to authorized rules and European directives and bear the CE indicator. A crucial issue for protection assurance is the accession in the products’ improvement section. By all indicates, the users’ knowledge about the correct use of a PTO drive shaft is essential. This means, that each and every users’ duty is to read and follow the protection recommendations.

Solution Deseription

Solitary Action Worm Equipment Reducer.

The reducer which product is 25~ninety produced of Aluminum alloy die-casting box,good searching in physical appearance,compThe output subassembly, which consists of the worm equipment and bearing cups and EPG s, loads onto a independent station for two simultaneous measurements. The equipment applies a predetermined load to opposing bearing cups and measures the complete stack height. At the very same time, a master worm engages and oscillates the output worm gear to locate the actual center of curvature for the equipment teeth. The device then steps the distance among this centerline and the rear-bearing cup.act in structure,rust proofing on area and tiny quantity to help save mounting room.

The reducer product of one hundred ten~150 is made of solid iron which casted with Aluminum mould.It`s good looking and solid, and can be used through the setting of multi-azimuth.

Very good radiating characterstic sales opportunities risk-free and dependability,and substantial efficiency for making use of.

The sturdy ability of loading make certain secure transmission,make considerably less vibration and sounds.

Varies of connecting framework for power input and torque output meet different demand-meritsthe design of box define and the established of foot hole with excellent versality is apt to many varieties of mounting.

The NMRV worm gearbox is new technology of merchandise by our manufacturing unit on the foundation of perfecting WJ sequence goods with compromise of sophisticated technology both at residence and overseas.It’s apprearance adopts advanced sq. box structure.It truly is outer human body is produced of large quality aluminium alloy die casting into forming.It really is tiny in quantity,light bodyweight,high in radiating performance,huge in output torque,clean in working and low sounds.It’s suitbale for all positions.

Technique for model picked

Please understand the pursuing at initial in order to delect the product of RV pace reducer effectively.

– Loading condition

– Velocity scope or ratio in application

– Operating condition and surroundings

– Installation place

Firm profile

HangZhouYinxin Electromechanical Facilities Co. Ltd

HangZhouYinxin Electromechanical Gear Co., Ltd.is a reward organization integrating improvement, design, creation and revenue,Major selling goods contain reducer motor,water pump,design machinery and parts,bearings,hardware and electrical tools,plastic goods,Labour defense appliance.Our company constantly follow the procedure concept which contains folks-oriented, innovation as the soul,be prepared for risk in occasions of peace, unremitting……

Application location

Certifications

Comprehensive Photos

Packing & Supply

|

Packaging |

||

|

Size |

five hundred (L) * five hundred (W) * 400 (D) |

|

|

Excess weight |

1.2 T |

|

|

Packaging Details |

The normal package deal is picket box(Measurement: L*W*H). If export to european international locations,the wood box will be fumigated.If container is also tigher,we will use pe movie for packing or pack it according to buyers unique request. |

|

|

Packaging |

||

|

Measurement |

five hundred (L) * five hundred (W) * four hundred (D) |

|

|

Weight |

1.2 T |

|

|

Packaging Specifics |

The regular package deal is picket box(Dimension: L*W*H). If export to european countries,the wood box will be fumigated.If container is as well tigher,we will use pe movie for packing or pack it in accordance to customers particular request. |

|

FAQ

Q1: Are you investing business or company ?

A: We are a manufacturer in ZJ China.welcome to our manufacturing facility to have a pay a visit to.

Q2: How we choose types and technical specs?

A:You can electronic mail us the sequence name & code (for illustration: WJ series worm gearbox) as well as necessity information, this kind of as motor power, output velocity or ratio, support aspect or your software…as significantly information as feasible. If you can provide some photographs or drawings, it is far better.

Q3: How is your price? Can you offer any low cost?

A: We will give the very best cost we can foundation on your wants and the quantities.

This autumn: How extended need to I wait around for the suggestions right after I deliver the enquiry?

A: Inside 12 hours.

Q5: What is your merchandise warranty interval?

A:We offer you 1 calendar year guarantee considering that the vessel departure day still left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are commonly used to metallurgical products, mining products, automation products, food equipment, packaging products, tobacco products and so on.

Best China manufacturer & factory EPG in Bokaro Steel City India superior quality worm gear speed reducer wholesale With high quality best price

Advanced thermo treatment equipment, such as network heat treatment oven, multi-use thermo treatment oven, etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Gearing Arrangement:

-

worm

- Output Torque:

-

200~915Nm

- Input Speed:

-

900~2800/min

- Output Speed:

-

11.3~35.1/min

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

superior quality wA PTO shaft transfers the power from the tractor to the PTO powered attachment. This enables the tractor to power a variety of tractor implements including flail mowers, wood chippers, rotary tillers, excavators, and more.orm gear speed reducer wholesale

- Application:

-

Solar Power, Food Stuff, Ceramics, Chemical, Packing, Dyeing, etc

- Color:

- Applications Worm gearboxes are available to suit the requirement of many applications. For food service and other washdown applications, worm gear boxes are available in durable, non-absorbent white or steel epoxy coatings. They are widely used in computers. The biggest benefit that the worm gearbox offers is the permanence of data written to them. Software that accompanies a worm gearbox usually enables to create a virtual drive based on the state of the disk at a given data in the past. They are also popular for backup. Worm cartridges store well and easily for long periods of time.

Blue(RAL5010)/Silver grey (RAL9022) Or On Request

- Ratio:

-

80,100,125,150,200,250,300 up to 4000

- Warranty:

-

1 Year

Supply Ability

- Supply Ability:

- 36000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Transparent box packaging, or color box packaging, it also can be customized.

- Port

- Ningbo/Shanghai

Online Customization

Jiaoxing superior quality worm gear speed reducer wholesale

Our products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.

Q1. How to choose a worm gearbox which meets our requirement?

A1: You can refer to our catalogue to choose the gearbox or we can help to choose when you provide

the technical information of output torque, output speed and motor parameter etc.

Q2. How is your price? Can you offer any discount?

A2: We will give the best price we can base on your needs and the quantities.

Q3. Do you offer any visiting?

A3: Yes! We sincerely invite you to visit us! We can pick you from airport, railway station and so on.

Also, we can arrange housing for you. Please let us know in advanced.

Q4. When is the best time to contact you?

A4: You can contact us by email any time, we will reply you as soon as possible.

Q5. How long will it take for the lead time?

A5: For our standard model, please refer to the different product pages to check the lead time.

For the OEM/ODM products, please contact us for further information.

Gear High Quality Price Ratio Reducer R Series Bevel Helical Gear Motor Worm Speed Reducer Box For Electric Motors

specialize in power transmission products Chain,pto shaft, agricultural gearboxes , CATV products, mechanical seal, hydraulic and Pheumatic, and promotional products.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Speed:

-

1400rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC

Supply Ability

- Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

Gear Reducer R Series Bevel Helical Gear Motor Worm Speed Reducer Box For Electric Motors

Product Description

SLR helical reducer has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibrationand high permissible axis radial load. This series can not only be combined with various kinds of reducers and variators and meet the requirements, but also beadvantage of localization of related transmission equipment.

Specifications:

1) Output speed: 0.6~1,028r/min

2) Output torque: up to 18,000N.m

3) Motor power: 0.18~160kW

4) Mounted form: foot-mounted and flange-mounted mounting

|

Product Name |

SLR Series Rigid Tooth helical reducer |

|

Gear Material |

20CrMnTi |

|

Case Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

|

Color |

Customized |

|

Noise Test |

Bellow 65dB |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

Expo& Customers

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

high Trusted and Audited Suppliers quality RV RW B14 flange RW40 worm gearbox vertical worm gear reducer servo motor supplier

Our item assortment consists of all varieties of helical equipment, spur gear, bevel gear, equipment rack, worm gear, sprockets,chains, bearings, pto shaft, agricultural gearboxes.

Overview

Fast Information

- Relevant Industries:

-

Manufacturing Plant

- Item name:

-

NMRV worm equipment reducer

- Housing Materials:

-

Aluminium alloy

- Content:

-

copper

- Warranty:

-

one-two Many years

- Ratio:

-

5-one hundred

- Bearing:

-

NSK Bearing

- Certification:

-

ISO9001

- Output torque:

-

two.6-1195N.M

- Output:

-

.sixty four-350rmp

- Intput:

-

750~3000rpm

Packaging & Supply

-

Lead Time

: -

Quantity(Luggage) 1 – three 4 – 5 >5 Est. Time(days) 5 10 To be negotiated

On-line Customization

Merchandise Description

NMRV NRV Sequence WORM Gear Speed REDUCER

In accordance to European standard of comparable product,we undertake high-good quality synthetic oil,imported renowned manufacturer seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful visual appeal,effortless set up,compact construction,minimal noise and high performance.

NMRV worm gear reducer absorbs innovative technological innovation at home and abroad. It has a novel and distinctive “sq. box” external structure. The box is stunning in condition and is produced of higher high quality aluminium alloy by die casting.

|

NMRV-063-thirty-VS-F1(FA)-AS-80B5-.75KW-B3 |

||||||

|

NMRV |

Worm geared motor |

|||||

|

NRV |

Worm reduction unit |

|||||

|

063 |

center dictance |

|||||

|

30 |

Reduction ratio |

|||||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|||

|

AS |

One output shaft |

AB |

Double output shaft |

|||

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|||

|

.75KW |

Electric motor power |

B3 |

Mounting situation |

|||

PRECISION BEVEL Equipment

worm and equipment: The gears are created of ten-one tin bronze (with substantial energy, corrosion resistance and excellent casting properties).

Worm adopts 20CR:carburized alloy structural metal (with substantial toughness, hardenability, wear resistance).

High Velocity Bearings and SKF Seals:Use artificial oil (friction agent: reduce temperature increase, decrease friction).

NMRV NRV Sequence WORM Gear Pace REDUCER MOUNTING DIMENSIONS

Output Flange Mounting Proportions

NMRV NRV Collection WORM Equipment Velocity REDUCER Attributes:

● The bodyweight of the NMRV reducer is reasonably mild. The shell is created of aluminium alloy. It has the advantages of mild weight, excellent toughness, exquisite look, substantial warmth dissipation functionality, lengthy provider existence, no noise and so on. It is simple to link with the motor.

● NMRV reducer is a much more functional transmission gear, and in the appearance style and its integration are far more in line with the requirements of the community than other types of reducers.

●The software area and popularity of the RV reducer made of aluminium alloy are even better than other sorts of reducer. It is a kind of reducer with large practicability, and also a mixture of superior engineering at house and abroad.

● NMRV reducer is extremely practical to join with normal motor, CVT, flange electromagnetic clutch brake unit, and does not need to have coupling. Appropriate for all-spherical installation, and the output torque is reasonably big, function reasonably smoothly and so on.

Our Company

Zhejiang provice EPT – one of the Greatest Transmission manufactrer in China Equipment Technological innovation CO., LTD

Our organization is situated in the metropolis of HangZhou ( Beautiful city where West lake located ) , Zhejiang provice Province of China.

We manage the goods of power transmission, our traces primarily include series merchandise in pace reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the adaptable capabilities, our products can be used in numerous fields: devices of waste drinking water treatment method, dredgers, chemical market, cranes, metallic operating mills, conveyors, paper sector, cement industry, cableways and so on.With the outstanding top quality and sensible price , our products take pleasure in a very good popularity from consumers and the peers all above the entire world.

Additionally, the R&D expenditure are each year growing for the purpose of greater assembly the new demands of our clients and adapting the new tendency of the industry.

Depending on the rules of honestly functioning and mutual reward, We sincerely look forward to cooperating with you.

Software location

NMRV NRV worm equipment speed reducer.

It is widely utilized in many fields this kind of as metallurgy, mine, printing, chemical market, textile, foodstuff, drugs, rubber and plastic,and so on.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In get to make certain the integrity of solution look, we will decide on cartons, wooden pallets and wood pallets according to client requirements.

●Delivery time: Every single reducer is produced and tested in accordance with strict and fixed techniques to make certain that the high quality is appropriate just before leaving the manufacturing facility and supply on time.

●Transportation manner: We will choose the most suited mode of transportation for our clients according to the fat and measurement of the products. We can also pick the manner of transportation according to the requirements of our customers.

●Receiving and after-product sales support: Following acquiring the merchandise, please check out whether or not they are in very good condition. We will give customers with best after-sales services.

FAQ

Q1: Are you a buying and selling firm or aproducer?

A: We are a manufacturer in Zhejiang provice Province, China. Our business owns the ability of production, processing, designing and R&D. We welcome your check out.

Q2: How we choose types and requirements?

A: According to the particular particulars of the requires from the element of enquiry, we will recommend the products’ types on synthesizing the variables of field of goods utilization, electrical power, torque arm and ratio…

Q3: How is your cost? Can you provide any price cut?

A: Our charges are always aggressive. If the customer can place a big purchase, we absolutely will enable price reduction.

Q4: How lengthy should I wait around for the opinions following I ship the enquiry?

A4: We will reply as shortly as feasible, twelve several hours at most.

Q5: What is your product warranty period of time?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are broadly used to metallurgical equipment, mining gear, automation gear, food equipment, packaging gear, tobacco products and so on.